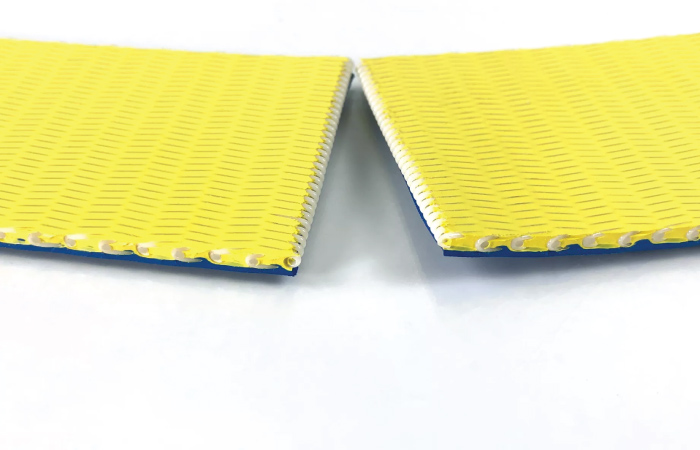

ZipLink® Product Range

ZipLink® is a breakthrough in belting design that combines cover materials with a structured link mesh that can be easily spliced at any length into a continuous belt without the need for special tools, presses or other equipment.

ZipLink® Belts offer users in a variety of different industries an outstanding range of product benefits such as a more flexible design which allows for the repair or replacement of just small sections of the belt.

ZipLink® Belts

Our product range now includes over 30 problem solving belt constructions combining time tested rubber cover materials with a structured spiral link mesh that can be easily spliced at any length.

The ZipLink® construction eliminates points of weakness because there is no loss of strength in the splice area, making the belts stronger so they last longer than belts of other seamed or fused materials.

ZipLink® is based on a low-stretch polyester monofilament carcass, which offers very high lateral stability for ease of tracking.

It’s common for ZipLink® users to reduce the time and personnel required to change belts by more than half.

Natural Rubber

General characteristics:

- Thermoset rubber

- Excellent abrasion resistance

- Excellent grip in wet and dry characteristics

- FDA

- Temperature range -40 °C to 121 °C

Main applications in belting:

- Paper and Cardboard Industry

- Wood Industry

- Inclined transportation

- Tobacco Industry

- Agriculture

Carboxylated Nitrile

General characteristics:

- Thermoset rubber

- Excellent abrasion resistance

- Excellent oil and fat resistance

- Good grip in wet and dry characteristics

- Temperature range -18 °C to 121 °C

Main applications in belting:

- Paper and Cardboard Industry

- Wood Industry

- Sugar Industry

- Detergent powder

- Metal Industry

Nitrile

General characteristics:

- Thermoset rubber

- Excellent oil and fat resistance

- Wear and impact-resistance

- FDA/USDA

- Temperature range -18 °C to 121 °C

Main applications in belting:

- Food processing (Meat & Poultry, Fish and Corn Flakes)

- Chemical Industry

- Textile (roll covering)

- Cardboard production

SBR

General characteristics:

- Thermoset rubber

- Good abrasion resistance

- Excellent grip

- Economical

- Temperature range -40 °C to 121 °C

Main applications in belting:

- General package handling

- Airport Industry (inside and outside terminal)

- Brick and Tile Industry

- Chemical Industry

- Carton Industry

Silam

General characteristics:

- Thermoset rubber

- Excellent release properties

- Good chemical resistance

- FDA/USDA

- Temperature range -54 °C to 176 °C continuous, -58 °C to 260 °C intermittent (depending upon carcass construction)

Main applications in belting:

- Tyre Industry (mixing department )

- Chemical Industry

- Shrink tunnels

- Food processing

- Leather and textile

Teflon

General characteristics:

- Thermoplastic

- Excellent release properties

- Excellent chemical resistance

- Excellent stain resistance

- Good oil and fat resistance

- FDA

- Poor abrasion and scuff resistance

- Temperature range -50 °C to 82 °C

Main applications in belting:

- Extrusion Industry

- Food Industry

- Chemical Industry

- Fiberglass Industry

Cotton / Felt

Characteristics:

- Temperatures up to 120 °C

Main applications in belting:

- Tyre Industry

- Cardboard

- Metal stamping

- Car Industry

- Aluminum extrusion